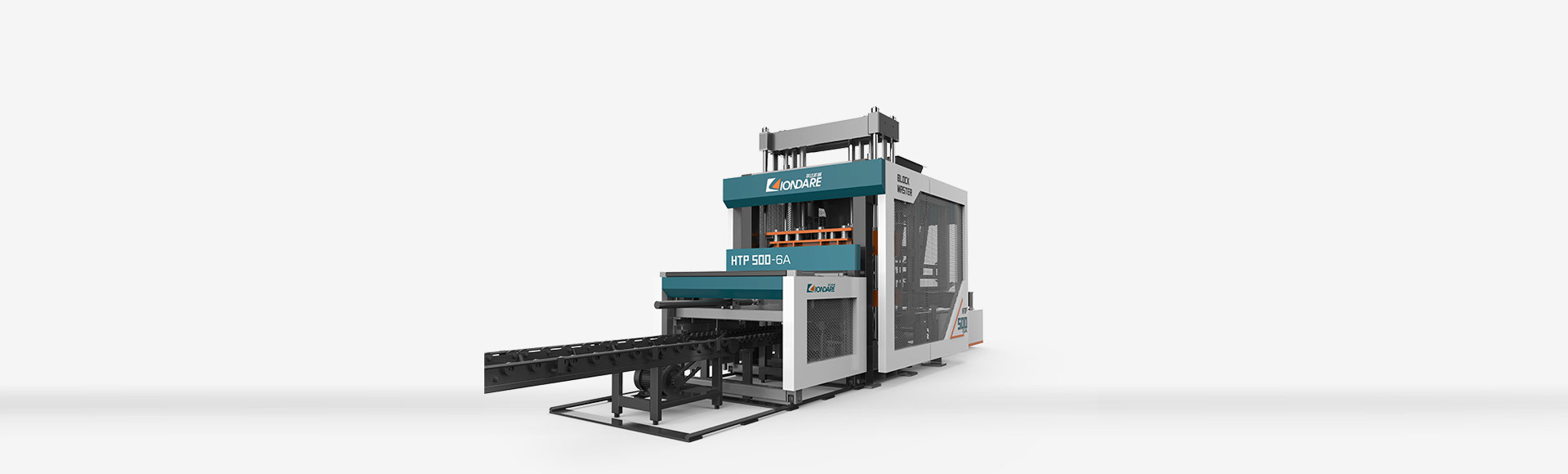

HTP500-6A Automatic Interlock Brick Vibration Machine

keyword:

Category:

Description

| Main technical parameters | |

| Capacity per stroke | 35 pieces/mold (color pavement permeable brick: 200*100*60mm) |

| 6 pieces/mold (color pavement permeable brick: 500*250*(60-80)mm) | |

| 3 pieces/mold (color pavement permeable brick: 600*300*(60-100)mm) | |

| 55 pieces/mold (non-standard brick: 238*113*48mm) | |

| 10 pieces/mold (single 8 grass bricks: 400*200*80mm) | |

| 16 pieces/mold (tic-tac-toe bricks: 250*190*75mm) | |

| 4 pieces/mold (water conservancy ecological slope protection brick: 495*295*(80-100)mm) | |

| Characteristics of the feeding bogie: | The new type of medium type fast swing fabric is adopted, the fabric speed is fast and the fabric balance column has no column angle, and the daily maintenance and cleaning are convenient and fast. |

| Vibration box and permanent magnet servo motor features | Using advanced percussion vibration system, the vibration source is driven by permanent magnet servo motor, good excitation effect, using motion control system to control servo motor amplitude, vibration width can be arbitrarily adjusted to the best state, and energy saving and other characteristics. |

| Hydraulic system features | The use of American SAWK high-performance duplex pump and Japan Oil Research Institute high dynamic proportional speed valve and proportional relief valve double adjustment has the advantages of stability, fast response, convenient parameter adjustment, good high and low pressure performance, low noise, energy saving and so on. |

| Electronic control features | PLC plus motion control system is used to control the time per node within milliseconds. Each action displacement is controlled within millimeters. |

| Mold frame balancing function and characteristics: | It adopts a unique upper beam release structure, with four guide columns as balancing tie rods and equipped with advanced synchronizers. Its characteristics accurately ensure the synchronization requirements of demolding, avoid damage to the bricks, and ensure that the bricks have good quality. |

| Molding cycle: | ≦19(s) |

| Vibrating force | 40KN |

| Main motor power | 30KW |

| Vibration motor | Permanent magnet frequency conversion 11KW |

| External dimension | (8000*4000*3100mm) |

| Pallet specification | 1120*880*23 |

| Vibration frequency | German frequency conversion technology. adjustable vibration frequency |

| Frequency converters: | 30KW (Shenzhen Sine) |

| Whole machine weight | 13.8TON |

| Main unit sealing: | 180*180*8 |

| Conveyor belt motor: | 3KW (manufacturer Defond) |

| Brick machine motor: | 1.5KW-1:2P (Defond) |

For many years, Lianda has focused on technological innovation, actively participated in industry exchanges, and absorbed the latest international advanced technological achievements. Through nearly five years of technological research and development, it has successfully developed a production line for "polystyrene particle lightweight aggregate concrete blocks", "ecological and environmental protection permeable bricks" fully automatic permeable brick forming machines, and a production line for "sintered ceramic permeable bricks" fully automatic support free CNC hydraulic forming machines with some excellent domestic energy-saving building materials companies. In order to achieve complete automation and reduce manual labor, we have successfully developed a fully automatic brick stacker. We can customize high or low position stackers according to customer needs.

Get product quotes for free

Related Recommend

HTP500-6A Automatic Interlock Brick Vibration Machine

HTP600-3 Automatic Interlock Brick Vibration Machine

IPFQ-10000 High-end Pallet-free Brick Press Machine

QYJ-4000 Automatic Single-cylinder Brick Press Machine