How to choose hydraulic brick machine

2022-12-07 15:56

1. Need to see professional technology: Whether it is the hydraulic brick machine industry or other equipment production industries, most manufacturers will boast how good and professional their equipment is, so as to promote investment customer investment from the heart. Here we remind customers that not only to listen to what the manufacturer says on the surface, we also need to conduct field visits, not only to conduct field visits to manufacturers, but also to conduct on-site inspections; Ask the boss of the production site how long is the brick machine used and how is the equipment performance? How is the production capacity, you need to ask clearly, do not listen to the manufacturer's words.

2. When buying a machine, it is necessary to look at the quality of the hydraulic cylinder, whether the motor meets the national standards, and the quality of the hydraulic pump station, which are related to the quality of the entire hydraulic system. Also look at the quality of the forming mold, if it is made of ordinary steel plate, without any treatment, the quality is definitely not guaranteed, maybe with 10 days, 8 days, or 1 month, 2 months, you have to change the mold, so that it increases the cost of the mold, resulting in an increase in cost, if you choose my factory carburizing mold, you can use 1 year - 2 years or even longer, this account we will calculate, which kind of mold is cost-effective, so buy a machine must be carefully examined.

3. Then it depends on whether the manufacturer's after-sales service is guaranteed, for which we have a professional after-sales team, tracking after-sales service, so that you have no worries.

According to the needs of users, determine the scale and determine the model. On-site installation and commissioning, training technology and equipment operation and maintenance personnel to teach waste resources concrete process technology and concrete ratio common sense. Create corporate profiles for users. Assist users to upgrade their systems and improve equipment production efficiency. Provide users with new molds at any time. Regular return visits to communicate with users in both directions. Assist users to establish production and quality management systems to ensure comprehensive development. Customers are regularly invited to the company to exchange burning-free brick technology and experience to enhance the competitiveness of all enterprises. Timely and accurately release the latest national wall reform policies and tax preferential policies for users, so that users can establish a marketing management system that adapts to the market economic environment. Manufacturers have been supplying accessories and various molds for a long time.

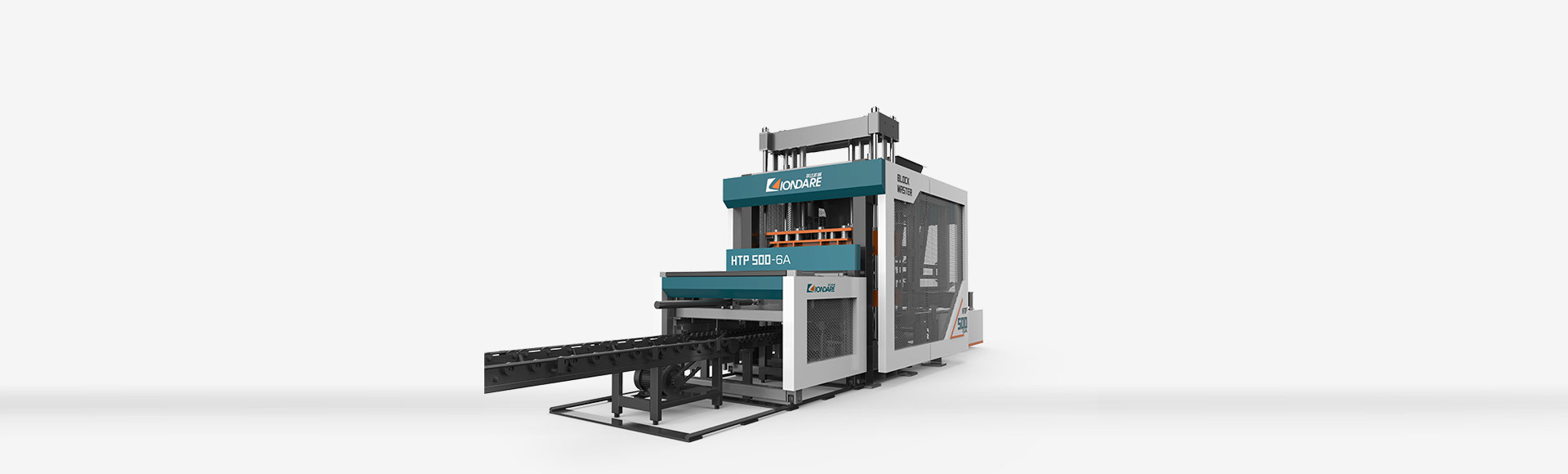

For many years, Lianda has focused on technological innovation, actively participated in industry exchanges, and absorbed the latest international advanced technological achievements. Through nearly five years of technological research and development, it has successfully developed a production line for "polystyrene particle lightweight aggregate concrete blocks", "ecological and environmental protection permeable bricks" fully automatic permeable brick forming machines, and a production line for "sintered ceramic permeable bricks" fully automatic support free CNC hydraulic forming machines with some excellent domestic energy-saving building materials companies. In order to achieve complete automation and reduce manual labor, we have successfully developed a fully automatic brick stacker. We can customize high or low position stackers according to customer needs.

Related information